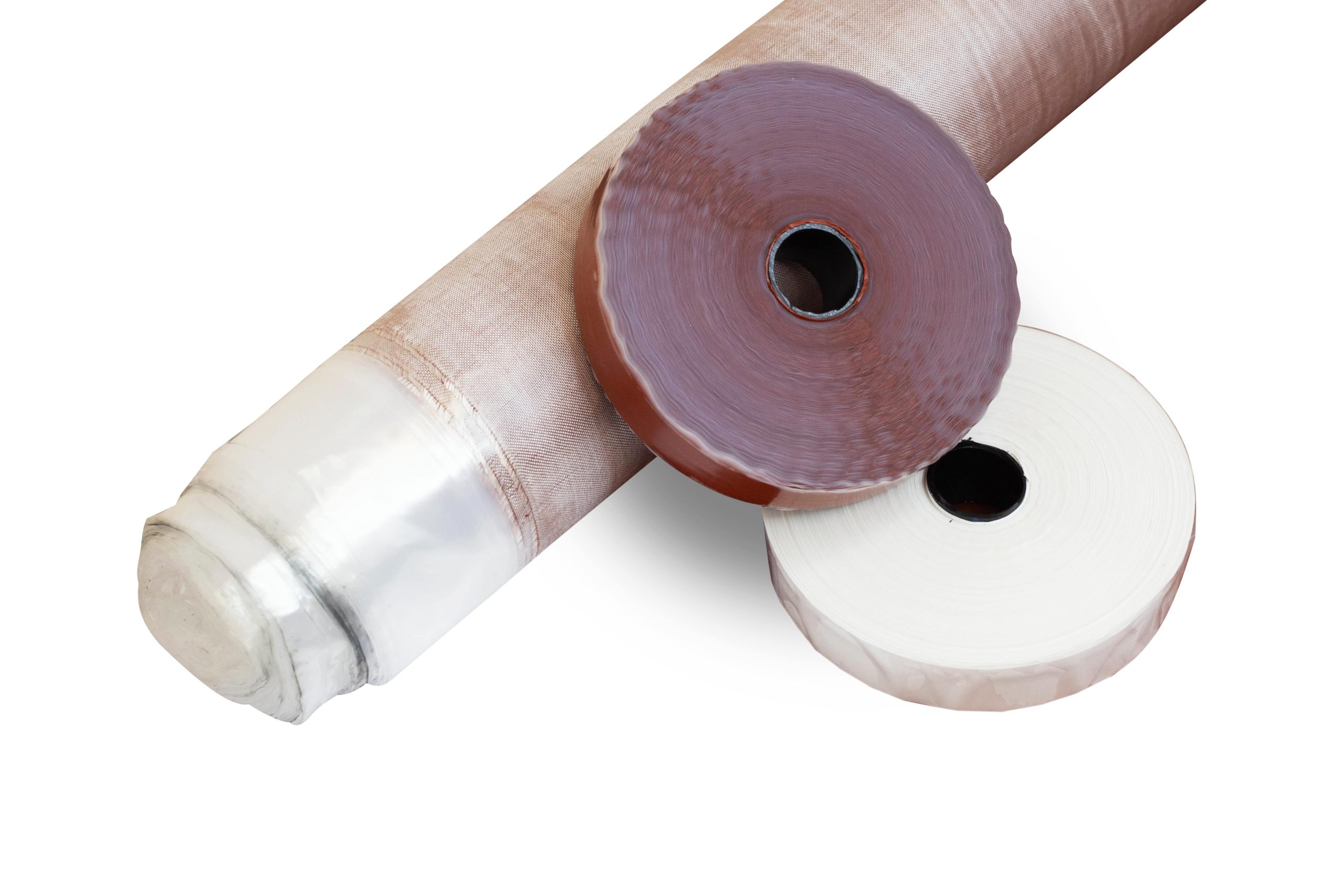

RETSAR heat-resistant electrical insulating self-fusing radiation cure rubber glass cloth

RETSAR heat-resistant electrical insulating self-fusing radiation cure rubber glass cloth is produced from fiberglass and organosilicon rubber using radiation curing method. RETSAR has self-fusing ability within 48 hours at (25±5) °C or within 3 hours with additional heating at (150±3) °C. It features high water resistance, resistance to ozone, ultraviolet rays, some oils (turbine, transformer oils) and some chemicals, complete absence of toxicity.

RETSAR heat-resistant electrical insulating self-fusing radiation cure rubber glass cloth is intended for use in the electrical industry as insulation for winding elements of electrical machines and devices operating in high humidity and high temperature conditions. RETSAR is used for flexible shunts and leads of AC and DC electrical machines, electrical harnesses, cables, busbars and current conductors. This material can be used both on its own and in combination with LETSAR tape.

Specification 38.103172-80

Properties

- self-fusing ability within 48 hours at (25±5) °C or within 3 hours with additional heating at (150±3) °C.

- high water resistance,

- resistant to ozone, ultraviolet rays, some oils (turbine, transformer) and some chemicals;

- completely non-toxic.

Technical characteristics

|

Parameters |

Value |

|

Working temperature range, °C |

-50 to +250 |

|

Rubber glass cloth autohesion after exposure at (25±5) °C for 48 h. or at (150±3) °C for 3 h.: — end-to-end application on self-fusing tape insulation (with rubber layer of the rubber glass cloth facing towards the tape) |

Monolithic self-fusion of rubber layers of rubber-glass cloth and rubber tape |

|

Nominal tensile strength, MPa, minimum |

39. 2 |

|

Nominal strength after thermal aging (72 hours exposure at 250 °C), MPa, minimum |

14.7 |

|

Dielectric properties: |

|

|

— volume resistivity, Ohm.cm |

1*1013 |

|

— dielectric strength, kV/mm, minimum |

20 |

Packing:

In the form of rolls packed in polyethylene bags (20 kg max.) with a polyethylene film between the rubber layers preventing self-fusing of the layers. Each roll is packed in a plastic bag and placed in a wooden or plywood case. Maximum weight of one package is 40 kg.

Guaranteed shelf life:

8 months

Guarantee:

The product is manufactured according to the Specification. The product meets the stated information within the shelf life and subject to storage conditions.